Reducing packaging waste and reusing it sustainably: With this goal in mind, HD Vision Systems is working together with the technology company Polysecure GmbH, the Karlsruhe Institute of Technology (KIT), Pforzheim University of Applied Sciences and the Fraunhofer Institute for Casting, Composite and Processing Technology IGCV on a research project over the next two years.

Consortium of 3 research institutions and 2 companies

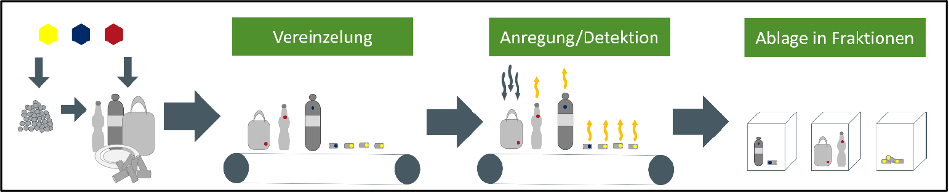

Together, the consortium is developing a system under the project name “Tasteful” to separate packaging by type. This should make it possible to sort plastic containers not only by type of plastic (PP, PE, PS, PET) but also by manufacturer. These could receive their packaging back after use. Thanks to the known material quality, they can then process the packaging again.

Detect, sort – and reuse plastic packaging with tracers

Tasteful is pursuing the approach with so-called tracers. These are fluorescent, inorganic markers produced by the Freiburg-based start-up Polysecure. Together with KIT, the company is developing new tracer substances. Fraunhofer IGCV then takes over the tracer identification using artificial intelligence. Finally, Pforzheim University provides support for the actual application: Waste management investigations and market entry fall within its area of responsibility.

Schematic representation of the tracer-based sorting process. 1.) Marking the packaging with fluorescent tracers; 2.) Separate material stream; 3.) Excitation, detection and classification of the tracers; 4.) Deposit in defined fractions and subsequent recycling; Graphic: Polysecure GmbH

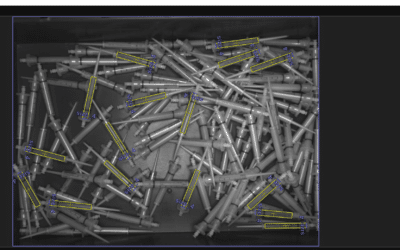

Object detection comes from HD Vision Systems

The quality inspection system from HD Vision Systems is employed to recognize the packaging used. The image recognition by the LumiScanX light field sensor is carried out by neuronal networks for the allocation of the recognized packaging. CEO and founder Dr Christoph Garbe comments:

“Packaging materials usually have very complex optical properties. Together with sometimes arbitrary deformations, these materials challenge optical measurement systems. We can master this with our light field imaging: it not only enables geometry measurement, but also the determination of the optical properties of the surfaces. Our neural networks are usually used in robot handling and for inspection tasks. For Tasteful, we are adapting imaging technology and algorithms to this new application.”

Project for more sustainability in waste management

The project has already started in February 2021 with joint project meetings and is expected to last two years thanks to funding from the Federal Ministry of Education and Research. In this way, Tasteful is making an important contribution to reducing plastic production as well as environmental pollution and contamination from waste plastics. “With our Machine Vision solutions, we are already helping manufacturing companies to avoid rejects and wastage. For us, it is therefore a logical consequence of also supporting the Tasteful project with our competences,” says COO Benedikt Karolus about the research project.

You can download the press release for the research project “Tasteful” here: