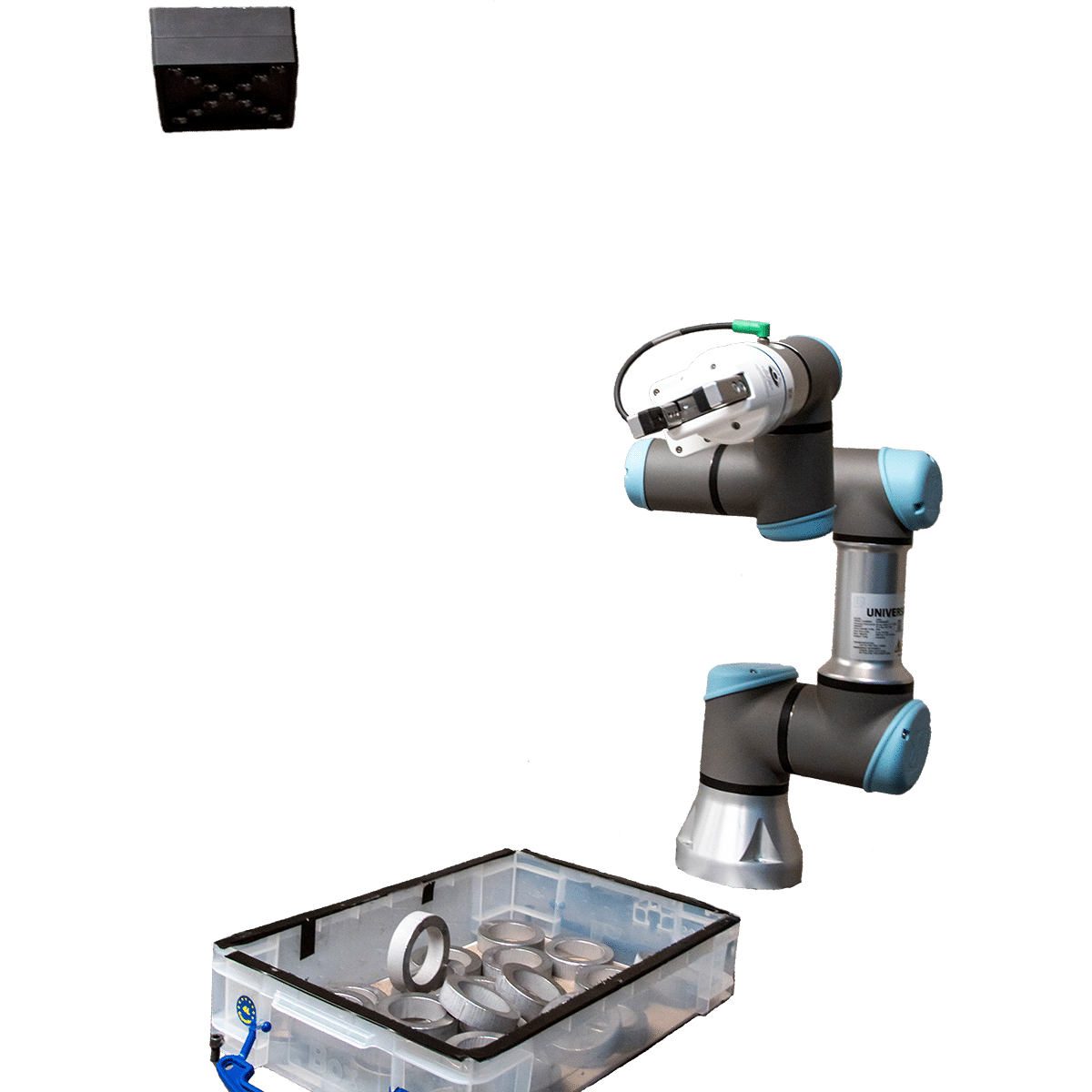

LumiScan VGR

Intuitive systems for bin picking and automated object handling of glossy and metallic parts.

- All-in-one Machine Vision solution with sensor & software

- System setup in only 15 minutes

- Compatible with common interfaces & robot types

Handle workpieces simply successful

- Reliably grip shiny objects and metal

- Less occlusion through multi-camera approach

- High depth of field – even at increasing distance

- Easy setup and operation – from set-up to in-line use in no time at all

- Load new CAD models of grippers and objects yourself at any time

- One system of hardware and software

Find out which LumiScan VGR solution is best for your automation task

LumiScan VGR provides solutions for your robot's tasks. Our configurator guides you to your perfect solution in 5 easy steps. Start your system configuration now! Max. size: 64.0 MB Max. size: 64.0 MBLumiScan VGR provides solutions for your robot's tasks

LumiScan VGR provides solutions for your robot's tasks

LumiScan VGR provides solutions for your robot's tasks

LumiScan VGR provides solutions for your robot's tasks

Start

Please enter a name for your project.

Parts to Pick

Alternatively: Upload a drawing (.stl) of the workpieces.

What is the surface of the workpieces to be gripped?

Alternatively: Upload an image (.png) of the workpieces.

Working Area

System Connection

Zeitrahmen

Contact Details

Data Protection

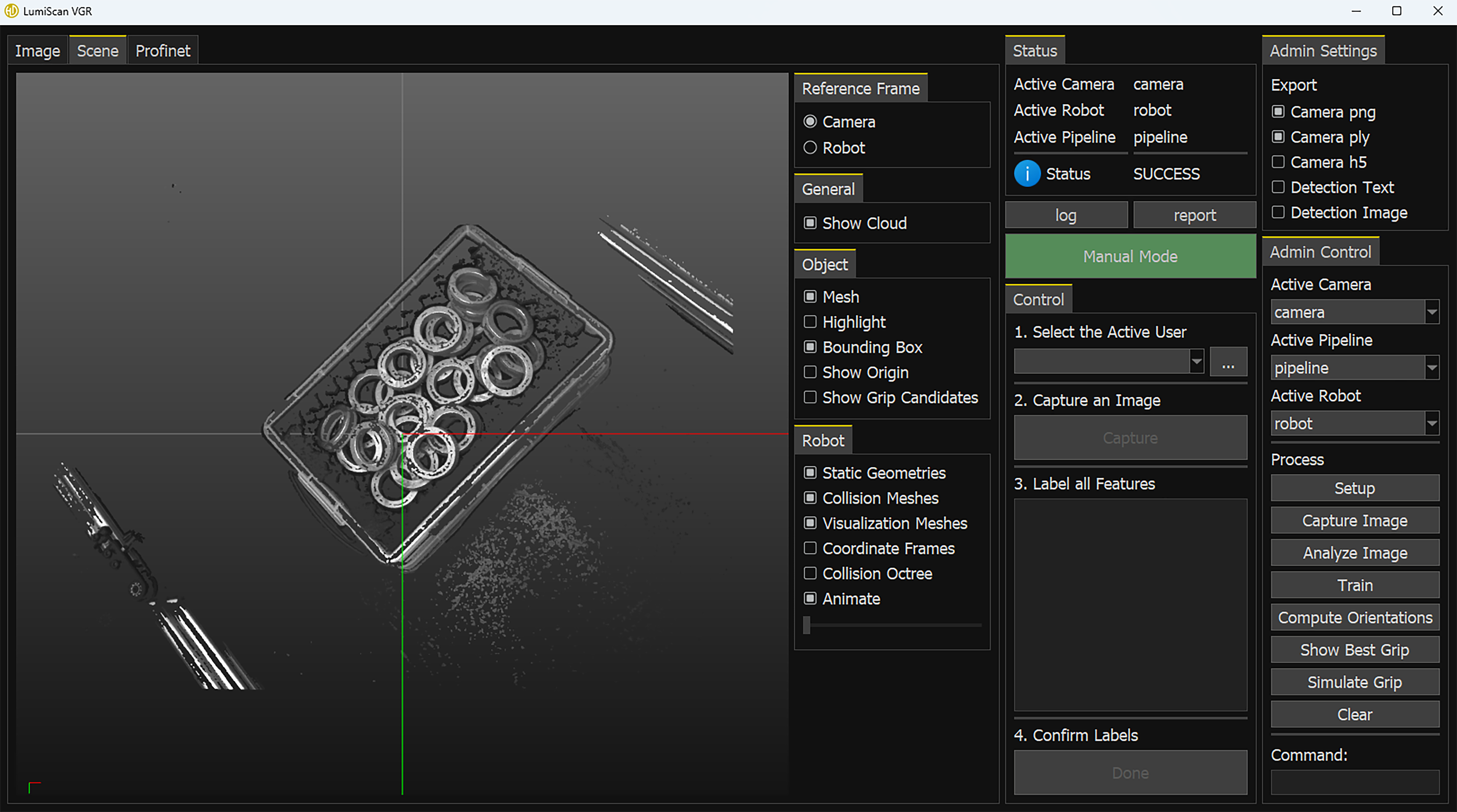

Intuitive Software

Simply get going

Clear user interface

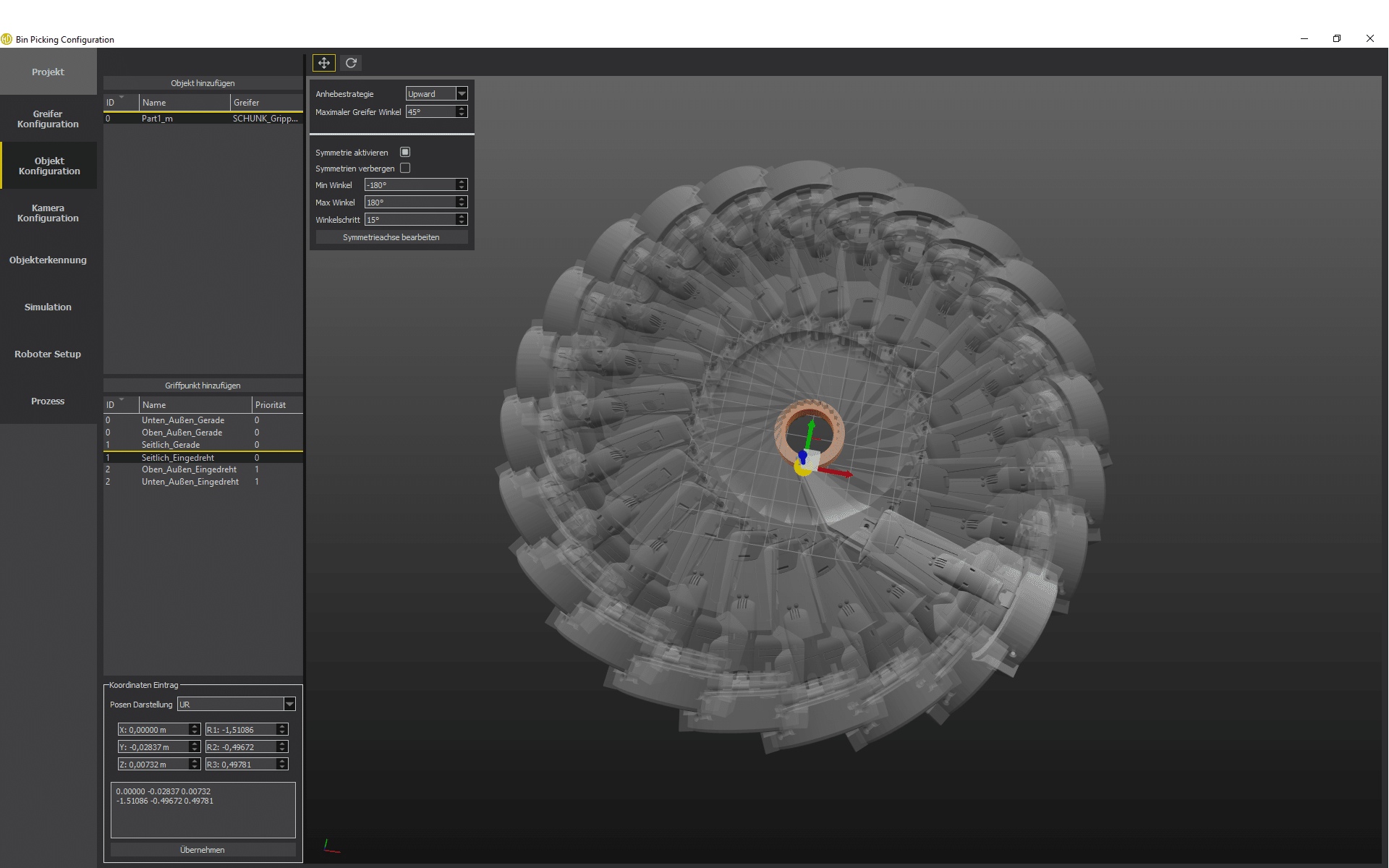

CAD-based object recognition: simply load gripper and object model as .ply, .stl or .stp

Define relevant points directly via Drag & Drop or coordinates

One point, many possibilities: Simply specify gripping point symmetries

Everything for the Connected Factory

- Connection via Profinet, OPC-UA and ctrlX AUTOMATION

- Ready-made interfaces for UR, KUKA, ABB and more

- Support for 6- and 7-axis

- Trigger signal via software or hardware

- Highly complex components? No problem! Pattern projector and other add-ons can be easily integrated.

Reliable path planning with full control

- Passive path planning directly to PLC or robot controller

- Complete collision planning in the entire visible space

- Delay-free: only 10 ms per planned path plus object detection

- Additional safety areas determinable

Reliable path planning with full control

- Passive path planning directly to PLC or robot controller

- Complete collision planning in the entire visible space

- Delay-free: only 10 ms per planned path plus object detection

- Additional safety areas determinable

Each LumiScan Object Handling System includes:

- 1x sensor LumiScanX (IP-54)

- 1x calibration target

- 1x software LumiScan Object Handling incl. license for one PC

- 1x 5m PoE cable

- 1x IPC (Windows 10)

- 1x quick start guide

- 1x Halcon license

Optional accessories:

- sensor-actor-cables

- ethernet cables

- Halcon licenses

- diffuse lighting

- flash lighting

- pattern projector

- and much more

Benedikt Karolus

Your personal contact partner

Get to know LumiScan VGR

Would you like to request a demonstration of LumiScan VGR? Or would you like to receive more information about our handling solutions? Send us your message! We will get back to you as soon as possible.