Agile software development is already a reality in many places. The waterfall model has had its day for project planning of software and code.

But agile machine vision?

Does variable project planning also work for automation projects whose output is to be a high-precision production plant?

We think: Yes! Due to its high software percentage, industrial machine vision can nowadays be implemented in an agile way better than ever before. Of course, this requires some adjustments to the method, but agile working is basically also suitable for the development of vision-guided robotics.

But first, let’s have a look at the basics of agile development:

Agile Project Management

Agile project management originated in software development. There, it became apparent early on that even the best-planned projects often fell behind schedule due to unforeseeable hurdles or even failed. A different method to meet these challenges was needed – and a highly flexible and adaptive framework for project management was born. Rigid adherence to a sophisticated plan thus came to an end, but agile project management did not become ruleless because of this!

Instead, the pioneers and founders of the concept decided to publish the so-called “agile manifesto“:

Interrelationships before processes

Project participants and stakeholders are an active part of agile project management. They are allowed and expected to participate fully with their knowledge, their questions and their creativity. For this purpose, processes can be changed or suspended at short notice – but a basic process framework should still be in place.

Function before documentation

The developed software should function first and foremost. Excessive documentation receives a lower rank.

Involvement before negotiations

Regularly involving the client and stakeholders in the development steps of the project takes precedence over prior contract negotiations. Not every detail can and must be clarified in advance – instead, regular consultation is the tool of choice.

Flexibility before planning

Being able to quickly and easily deviate from the previous plan without losing orientation – at the latest since the pandemic, we know how valuable flexibility can be for plans. The agile manifesto has already anchored this principle in its foundations.

Building on these principles, numerous software companies and start-ups have switched to agile development in recent decades. But that’s not all: this agility has been transferred to more and more other areas and departments. In addition, agile sub-types such as Scrum or Kanban have developed to facilitate implementation even more, depending on the needs.

It is therefore only logical that this development is now also reaching industrial production and plant engineering.

Transferring Agile Project Management to Machine Vision

Clearly, a large part of today’s Machine Vision in industry is also based on algorithms and software. Recently, machine learning has also become increasingly important. The use of these AI algorithms makes the software development process even less predictable and more volatile: The neural networks used in industrial Machine Vision in particular are too complex to be described completely manually.

Working in an agile way with the help of Agile Machine Vision is therefore a perfect fit at these interfaces.

However, it should not be underestimated that machine vision is not a software-only project. The hardware and integration into the entire production plant are the central counterpart to the software. Without it, there is no productive use. And this is also the crux of the matter:

Agility applied to industrial plants

Highly complex automation systems consisting of countless components and elaborate robotics do not always offer the necessary degrees of freedom to make agile changes in the ongoing project. What is needed here is either appropriate planning, e.g. sufficient buffer space and alternatives already considered in the planning phase. Or an image processing solution that is as versatile and agile as possible, because even the smallest changes in the setup can affect the image performance of cameras. A different lighting situation, shocks, changes in location or even the presentation of new workpieces can easily become an obstacle. In this case, not only adaptable software is needed, but also hardware. Agile Machine Vision must productively combine these two aspects.

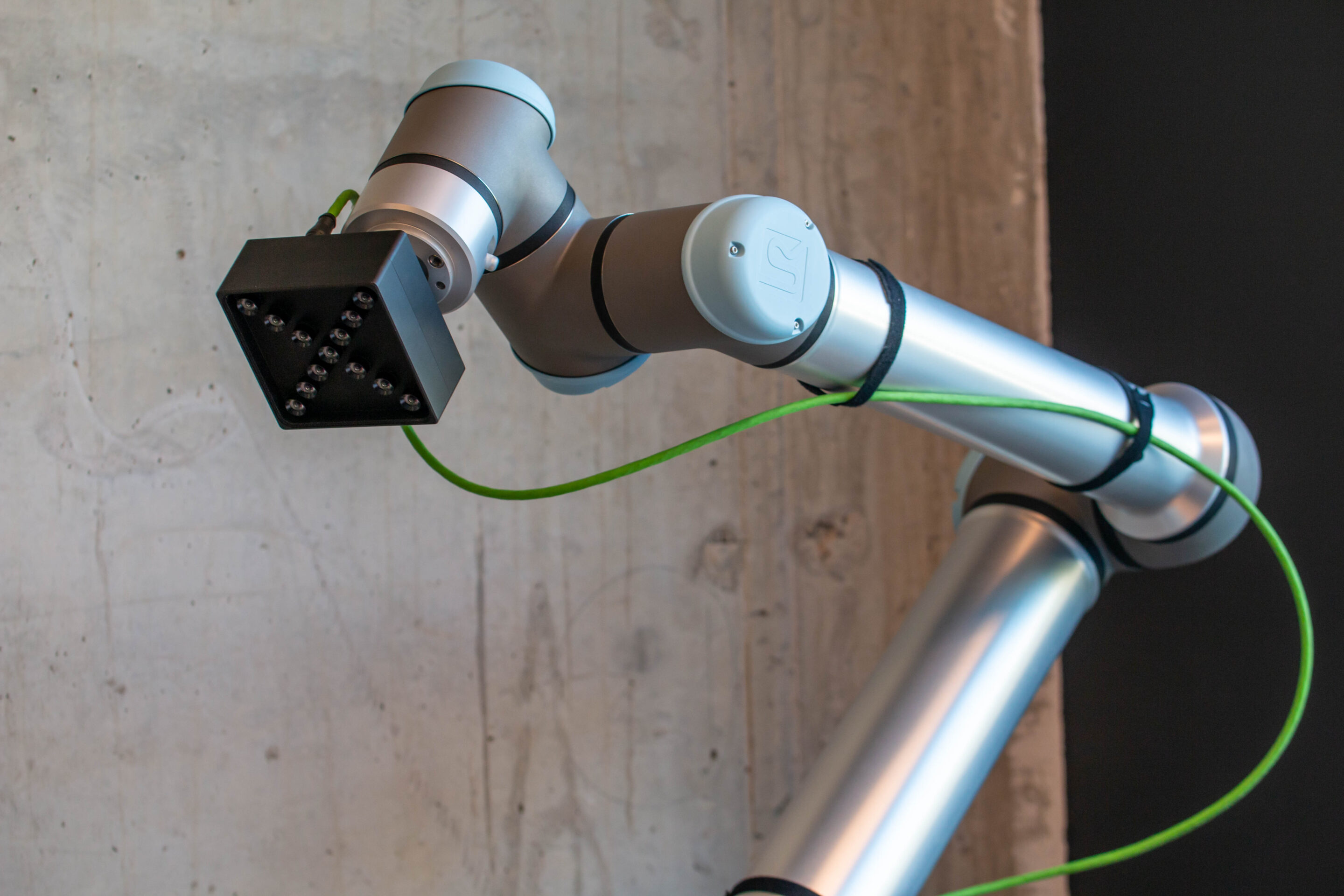

One sensor for it all: LumiScanX: LumiScanX

LumiScanX makes it easy to close many of these planning gaps: Not only can the compact 3D light field sensor be mounted almost anywhere with minimal loss of space, it also offers the option of subsequently changing the range and distance of objects by changing the lenses. Due to its unique design as an industrial light field sensor, the LumiScanX offers robust object detection – especially with metallic or reflective surfaces and complex shapes. The sensor thus offers the necessary flexibility for agile Machine Vision on the factory floor.

Use LumiScanX for visual quality inspection of metallic and complex workpieces

Agile development with AI

But it is not only the hardware requirements that need to be adapted to agile project management. Classical Machine Vision is strongly limited to a specific object type. The respective image processing solution is firmly attributed to this and developed. Other objects can often only be integrated into the existing software with great effort or not at all.

Although agile software development can also think about and plan for potential enhancements in Machine Vision, more and more often classic algorithms are no longer sufficient for the highly complex recognition and inspection tasks. Development then relies on AI and machine learning. Of course, these must also be adapted for their respective tasks.

Yet: when properly integrated into an machine vision project, neural networks can be exchanged or extended at the click of a button. Regardless of whether additional defect types are then found on the known parts or a new workpiece runs over the assembly line – agile adaptation is no problem.

Conclusion: Agile Machine Vision is becoming increasingly relevant

Increasing automation and growing computing power are driving industrial Machine Vision significantly forward. But it is precisely because of the increased possibilities on the software side that project management must adapt to these changes.

Agile Machine Vision bridges the gap between the already established agile software development and the previously rigid hardware development.

This results in new requirements for sensors and equipment. These, in turn, enable manufacturing companies to break new ground in the previously non-economic automation of complex parts.