In industrial machine vision, stereoscopic vision is standard – but it’s not the only way to capture images. Light field technology offers another approach that delivers a more precise result thanks to extensive information.

One or the other may still remember; from 2014 to 2016, it was possible to purchase a so-called “light field camera” on the end customer market. The highlight: Shots taken with this digital camera made it possible to determine the focus point on photos afterwards in a software. Computational photography” was born. The captured scene was always absolutely sharp – and even a 3D simulation was possible. Unfortunately, the company behind it later decided to focus entirely on the industrial application of VR. The product was scrapped.

But the camera’s name said it all: like all cameras in this class, it recorded the entire light field of a scene. But what is hidden behind a field of light? Why is it so special and why does it represent a real stroke of luck for industrial machine vision? These are the questions we want to explore today.

Light field and plenoptic function

The light field is a physical concept and describes the totality of all light-related information in a scene. This includes:

- A beam of light (straight line) from the scene being photographed, determined by two angles θ and ζ.

- A location of observation of the light beam (Vx, Vy, Vz).

If necessary, the variables of the function can be extended by the wavelength λ of the light for colored recordings and the time t for a video recording.

These individual aspects result in the actual plenoptic function P(θ, ζ , λ, t,Vx , Vy , Vz). On this basis, all further calculations for the use of light field technology can be made.

Light field technology – or the attempt to capture all light information as an image.

With the help of the plenoptic function, it can be determined exactly from which direction the light came in the photographed scene.

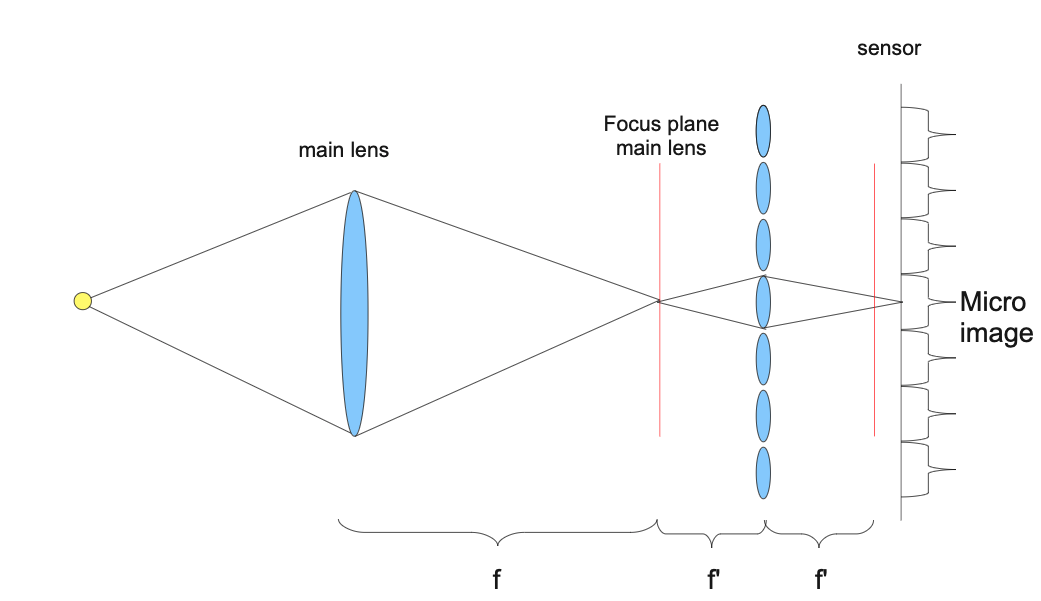

Recording a scene with a downstream camera array that generates numerous micro images. These are then digitally merged into one image.

In order to additionally calculate the camera position and thus also the associated focus point, light field technology relies on camera arrays with multiple lenses. This grid breaks up the respective light beams into a cone once again – modern algorithms are thus able to calculate an exact angle of entry and thus the position of the originally recorded point. This relativizes the position and focus point of the image. Corresponding software can now offset both as desired – the image is sharp everywhere and can be adjusted as desired. The angle of view can also be varied afterwards.

What is comprehensive image information for?

In industrial machine vision, this information provides additional potential for difficult tasks. For example, light field cameras capture complex materials without any problems, even if they are shiny or shimmering, for example. In a stereoscopic image, the gloss point would instead often be misinterpreted as a surface point. This leads to errors in depth estimation. Overall, for stereo approaches, the surface must be assumed to be Lambertian – that is, with matte reflectance properties, which is never achieved in reality. The light field technology also has an advantageous effect in factory halls where no active lighting is desired, since the light field is very robust. With the camera arrays used, even regular ambient light is enough for a good image.

Another important feature is that the light field can be used to calculate exact positions in the images. The step to a detailed point cloud, to quantified surface properties or to 3D simulation is thus only very small. This in turn can then be used for various industrial applications – such as object recognition, bin picking or quality inspection.